Lino® Simplify is an Add-In for Solidworks that will automate the process of model simplification and will help you to get the result that best fits your application. Companies choose to simplify their 3D models for different reasons:

- Creating layouts, e.g. for project planning

- Protect intellectual property, when sharing files

- Model respectively design obfuscation

- Prevent reverse engineering

- Increased performance through data reduction

- To generate Web and VR graphics

Lino® Simplify Scenario 1 – Simplifying assemblies for layouts

Subtitles available in German, English and Dutch.

Lino® Simplify Scenario 2 – Share 3D models

Subtitles available in German, English and Dutch

Lino® Simplify Scenario 3 – Part simplification

Subtitles available in German, English and Dutch

Due to increased globalization, more 3D models are being exchanged with third parties. This involves the risk of unintended use of the models. Companies can prevent this by sending simplified and obfuscated 3D models. This will protect your intellectual property and make reverse engineering very difficult.

Another reason to use simplified models is to build layouts. Conventional 3D CAD models contain too much information. By simplifying your models, unnecessary details are removed. This will decrease graphics load, loading times and improve handling of files.

The simplification process is a fully automated process. So once the correct settings are set, Lino Simplify will do its magic. Lino Simplify works for both part and assembly files and will process all dependent files as part of the simplification process.

If we’ve sold only one additional system because we were able to show the customer a convincing 3D layout quickly, then our investment and the internal overhead have more than paid for themselves.

RALF BROTZEL, ADMINISTRATOR CAD, PDM AND SAP ERP, BYSTRONIC GLASS, NEUHAUSEN, GERMANY

Functions

Different settings will affect the simplification result:

- Global Settings

- Settings Parts

- Settings Assemblies

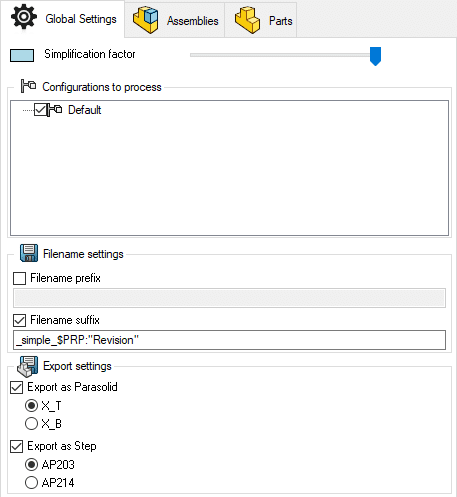

Global Settings

In this tab, users can set generic simplification settings like configurations to process, filename pre- and suffix and the level of simplification. Users can use file property values in the prefix/suffix. This allows you e.g. to create unique files per revision.

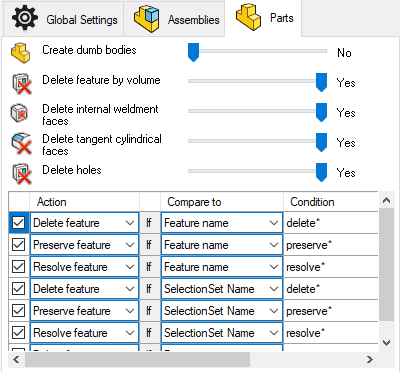

Settings Parts

Part settings affect the simplification of individual parts and parts that are used as component in assemblies.

Use Create Dumb Bodies to delete all feature information from the model. This will give you the best result to prevent reverse engineering and will automatically disable the option to preserve mates.

Users can choose to delete features based on their relative volume.

Furthermore, users can choose to delete internal faces of weldment or to delete cylindrical faces. This last option will e.g. delete faces of bends in sheetmetal models.

Besides that, users can choose to delete holes from the model. Users can also use conditions to delete, preserve or resolve features based on their name. Lino Simplify provides tools to easily (batch)rename features for the right application. Selection sets can also be used to delete, preserve or resolve features, regardless the name of the feature.

All these settings will work best on Solidworks models, but also imported geometry will be simplified.

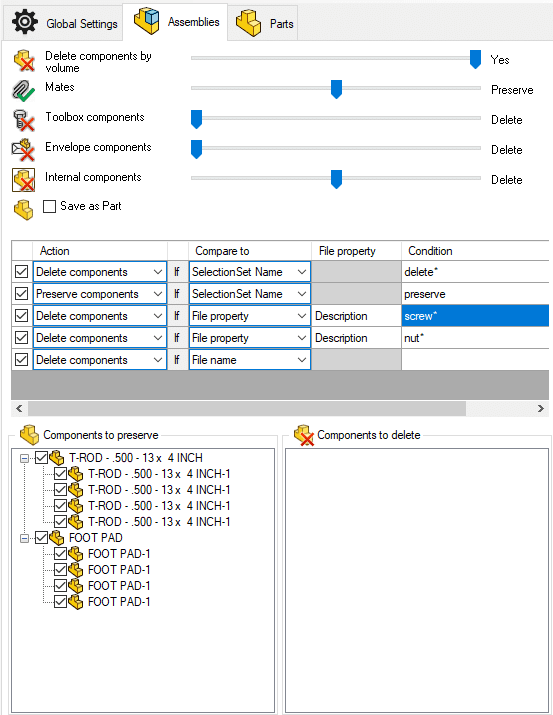

Settings Assemblies

This tab contains all settings that will affect (sub)assembly files.

Users can set whether components should be deleted by their (relative) volume. This will result in small components being deleted.

Users can set whether they want to delete or preserve different component types (envelop and toolbox components).

Furthermore, users can set whether they want to delete internal components or if they would like to get a part file as output file. This will give you the best result to prevent reverse engineering.

Users can also define to delete or preserve components by file property or by file name. Besides that, users can also specify the name of selection sets to delete or preserve components.

The last option is to manually select the components to delete or preserve. These settings make our users very flexible in influencing the simplification result.

Output

The output of the simplified geometry is always in a single file – even for assemblies. For single parts, features can optionally be converted into a “dumb” import body. An assembly can be output either as a simplified assembly with virtual components or as a Solidworks single part (i.e. without assembly structure).

In addition, the user can determine for individual parts such as assemblies whether Parasolid and/or STEP files are to be exported as well. Furthermore, a report is output as a PDF file by default, which documents the simplification results achieved in the form of comparisons of the states before and after the simplification.

Productivity Tools

- Replace files

Lino Simplify allows you to easily replace the simplified model with the original file when used in another assembly and vice versa. This makes it very easy to exchange models with the simplified or original version of a file. - Open files

You can also easily open the simplified model of a file and vice versa. This makes it very easy to find the simplified or original version of a file. - Join Bodies

This function is only available for parts and will join all solid bodies in the model. - Convert To Part

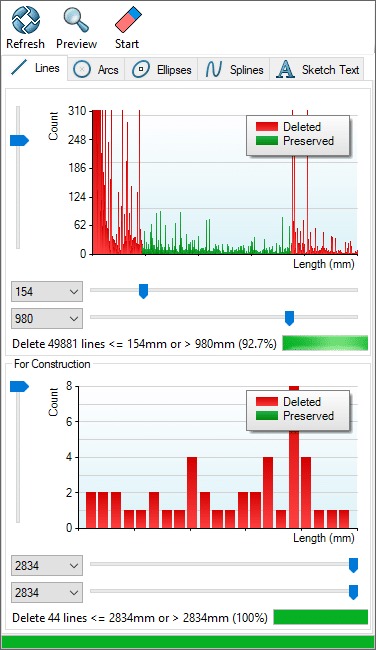

Convert To Part saves an assembly as part. But instead of Solidworks, multiple configurations are supported. Besides that, all solid bodies are joined to minimize the amount of solid bodies. - Sketch Cleaner

Besides tools to create simplified models, Lino Simplifier also provides productivity tools like the Sketch Cleaner. This helps users to cleanup large sketches (of imported files) by deleting sketch segments by their size, radius or character count.The active sketch will be analyzed, and the user can easily set which sketch segments to delete by moving sliders per sketch segment type.

Related solutions that might be of interest to you:

Do you have questions about our portfolio, would you like a consultation or would you like to arrange an individual live demo of our 3D configuration solution based on your models?

Please use the form below to contact us. We will subsequently contact you as soon as possible and send you the requested information.

Fields marked with * are mandatory.

Lino GmbH Mainz

Phone +49 6131 32 785-10

E-Mail info@lino.de

Lino GmbH Bad Mergentheim

Johann-Hammer-Strasse 24

97980 Bad Mergentheim

Germany

Phone +49 7931 95 349 96

Email info@lino.de

Kompetenzen

- Beratung, Support

- Software-Entwicklung

Lino GmbH Austria

Rossa 25

3823 Raabs an der Thaya

Austria

Phone +43 2845 70119

E-Mail austria@lino.de

Kompetenzen

- Auftragsbearbeitung

- Beratung, Support

- Geschäftsführung

- Schulung, Ausbildung

- Software-Vertrieb

Lino GmbH Stuttgart

Friedrichstr. 15

70174 Stuttgart

Germany

Phone +49 711 490 508 45

E-Mail info@lino.de

Kompetenzen

- Beratung, Support

- Software-Vertrieb

Lino GmbH Dresden

Chemnitzer Strasse 117

01187 Dresden

Germany

Phone +49 6131 32 785-10

E-Mail info@lino.de

Kompetenzen

- Beratung, Support

- Schulung, Ausbildung

- Software-Entwicklung

- Software-Vertrieb

Lino GmbH Bremen

Hermann-Koehl-Strasse 7

28199 Bremen

Germany

Phone +49 421 96 01-180

E-Mail info@lino.de

Kompetenzen

- Beratung, Support

- Schulung, Ausbildung

- Software-Vertrieb

Lino GmbH Mainz

Große Bleiche 15

55116 Mainz

Germany

Phone +49 6131 32 785 -10

E-Mail info@lino.de

Kompetenzen

- Auftragsbearbeitung

- Beratung, Support

- Geschäftsführung

- Schulung, Ausbildung

- Software-Entwicklung

- Software-Vertrieb